Supreme Lifeline C-PVC

Supreme Lifeline C-PVC plumbing system manufactured using world’s best Japanese material and technology is a safe long lasting and cost effective solution for the hot and cold water. Supreme Lifeline C-PVC plumbing system is designed to withstand high temperatures, making it ideal for both residential and commercial applications. With excellent resistance to corrosion and scaling, these pipes ensure a maintenance-free plumbing solution. The advanced Japanese technology used in manufacturing guarantees durability, leak-proof performance, and an extended lifespan. Suitable for both hot and cold water distribution, it is a preferred choice for modern plumbing needs. Available in various sizes, fittings, and specifications, Supreme Lifeline C-PVC is a trusted name in the industry. UK casino online.

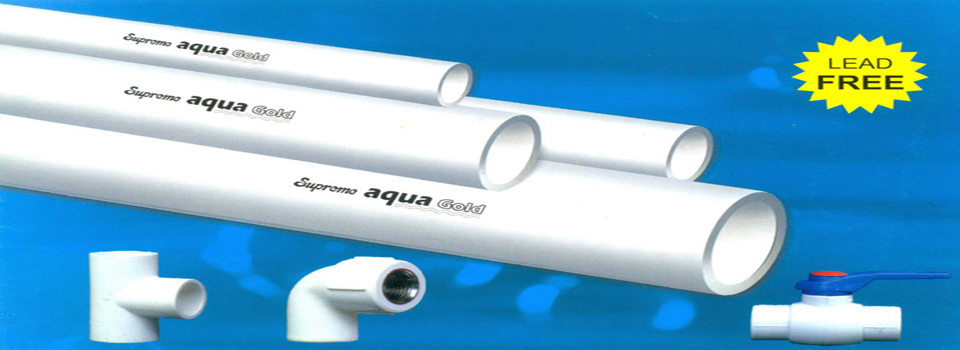

Supreme Aqua glod U-PVC

Supreme “lead free” aqua gold high pressure uPVC solvent weld plumbing system is the most suitable, easy and economical solution for distribution of potable water. Supreme Aqua Gold U-PVC pipes are engineered for high-pressure water distribution, ensuring efficient and safe transportation of potable water. The lead-free composition makes it an environmentally friendly and health-conscious choice. With a strong solvent weld system, installation is hassle-free, requiring minimal maintenance over time. These pipes are highly resistant to bacterial growth, rust, and chemical reactions, ensuring water purity. Whether for domestic, industrial, or agricultural use, Supreme Aqua Gold U-PVC provides a cost-effective and reliable solution. Play online bingo games.

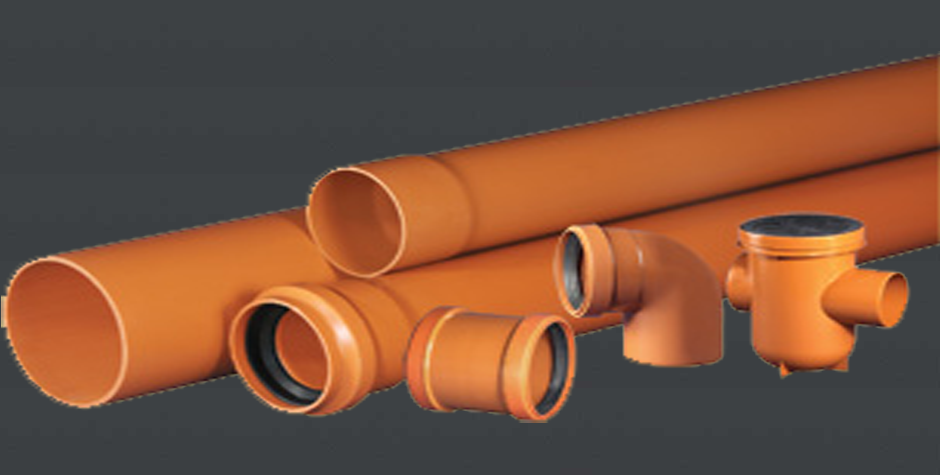

Supreme Eco-drain pipes

Eco-drain pipes are not solid wall pipes but have a unique wall structure i.e. with a number of “holes” in the wall thickness in longitudinal direction. Eco-drain pipes are specially designed to enhance the efficiency of drainage systems with their unique perforated wall structure. The longitudinal holes in the pipe walls reduce weight while maintaining high structural integrity, making them ideal for underground drainage applications. These pipes offer excellent flow capacity, reducing blockages and ensuring smooth wastewater management. Eco-drain pipes are widely used in sewage, stormwater drainage, and rainwater harvesting systems due to their durability and long-lasting performance. Their lightweight design makes them easy to install, reducing labor costs. While considering efficient drainage solutions, you might also be interested in exploring casino utan spelpaus.

Why Velani Enterprise

-

Supreme’s Authorized distributor sines last 35 years in Vadodara District

As a trusted partner of Supreme, we have been delivering high-quality plastic piping solutions for over three decades, building a reputation for reliability and excellence. For those interested in online entertainment, you can also explore gambling sites uk. -

Having a complete solution in plastic piping division

We offer a diverse range of products, catering to various sectors, including residential, commercial, and industrial applications. Our expertise ensures that we provide the right solutions for different plumbing needs. For some online entertainment, you might also consider checking out online roulette uk. -

Provide delivery in 24 hours

We understand the importance of timely service, which is why we prioritize fast and efficient delivery, ensuring that our customers receive their orders within 24 hours. -

A wide range of supreme plumbing pipes & plumbing system

From C-PVC and U-PVC pipes to advanced eco-drain systems, we stock a comprehensive selection of Supreme products to meet every requirement. Our product range ensures durable, leak-proof, and long-lasting performance for diverse applications.